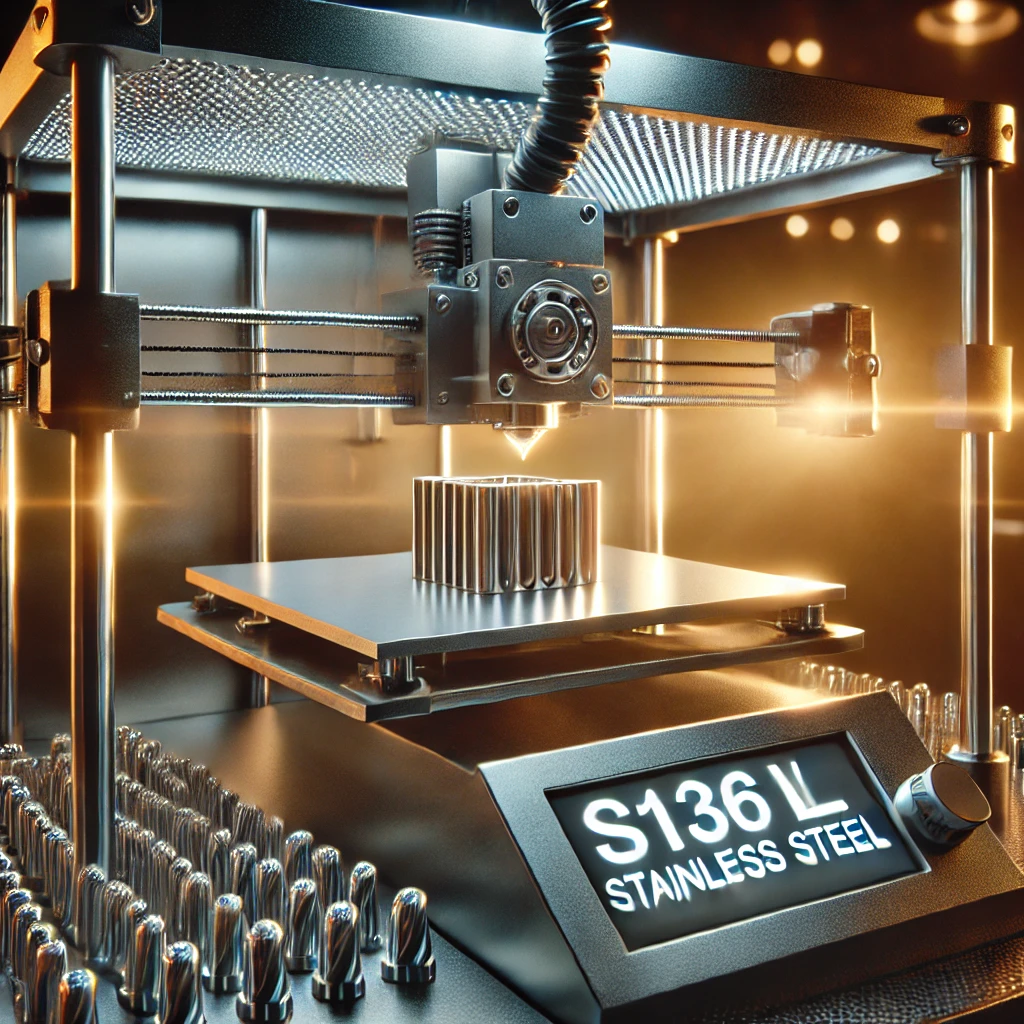

Wisthink has successfully developed an advanced Fused Deposition Modeling (FDM) 3D printer capable of high-quality printing with S136L stainless steel. This achievement marks a significant milestone in metal 3D printing, overcoming long-standing industry challenges.

S136L stainless steel is a high-performance material known for its exceptional corrosion resistance, wear resistance, and machinability. It is widely used in automotive manufacturing, aerospace, mold production, and biomedical applications. However, 3D printing this material presents significant technical hurdles, as it requires a stable, high-temperature environment. Even slight temperature fluctuations can cause deformation, making it one of the most challenging materials for FDM 3D printing.

Wisthink’s newly developed FDM 3D printer has successfully tackled these challenges, ensuring precision and reliability in the printing process. This breakthrough opens new possibilities for the adoption of metal FDM 3D printing in various industries, providing cost-effective and high-performance manufacturing solutions.

“This innovation represents a major step forward in metal 3D printing,” said a spokesperson from Wisthink. “Our proprietary technology enables high-precision manufacturing with S136L stainless steel, offering new opportunities for industries requiring durable and complex metal components.”

With this success, Wisthink aims to further expand the applications of metal FDM 3D printing, bringing efficient and accessible metal additive manufacturing to a broader range of industries.

For more information, please contact:+44 07453951497