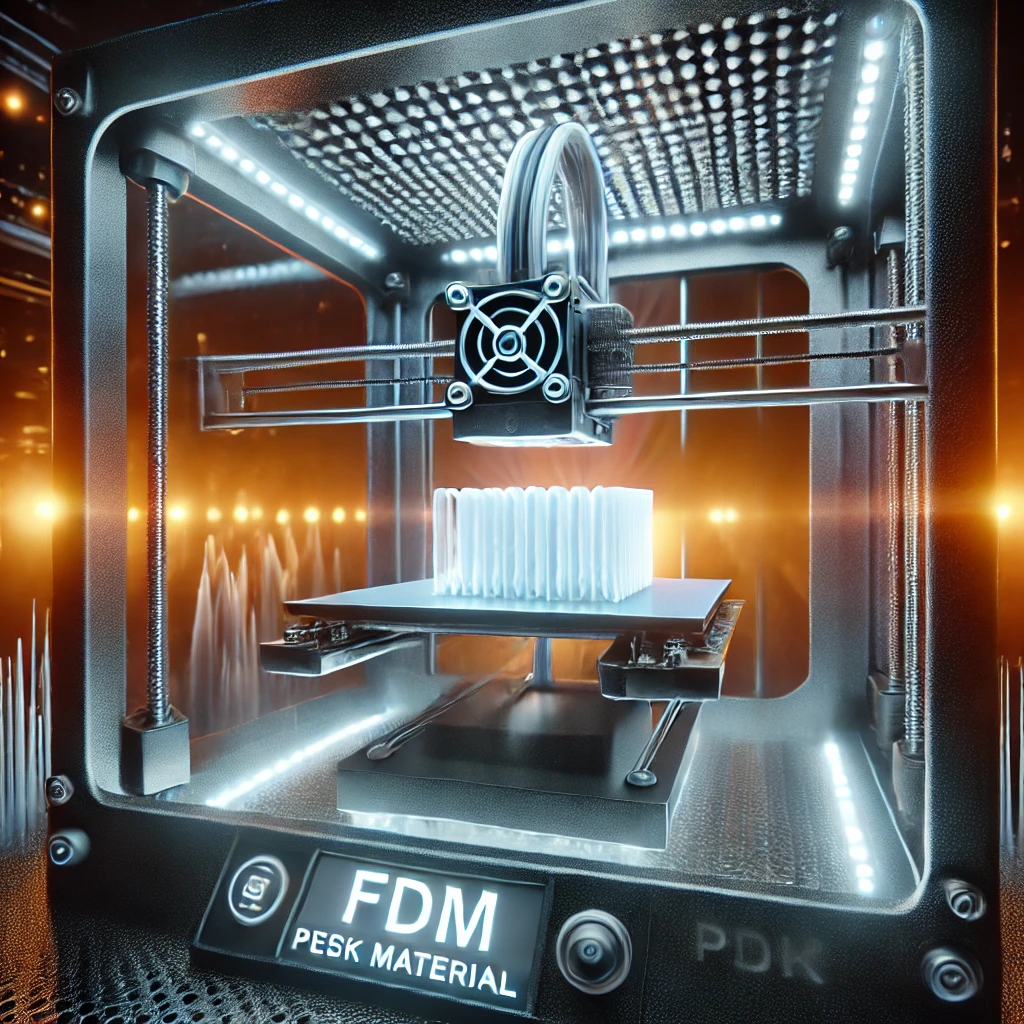

Wisthink has made significant progress in high-temperature Fused Deposition Modeling (FDM) 3D printing with the successful completion of PEEK material printing tests. This achievement marks another milestone in advanced material 3D printing.

PEEK (Polyether Ether Ketone) is a high-performance engineering plastic known for its exceptional heat resistance, self-lubrication, chemical stability, radiation resistance, and electrical properties. With outstanding mechanical performance, PEEK is widely used in automotive, aerospace, and biomedical industries. It is often regarded as one of the most promising materials of the 21st century. However, PEEK has a high melting point of 343°C and is highly sensitive to temperature variations. Printing with PEEK requires a consistently high-temperature environment, as even slight fluctuations can lead to deformation, making it a well-known challenge in 3D printing technology.

Wisthink’s independently developed high-temperature FDM 3D printer has successfully overcome these challenges, ensuring stable and precise PEEK printing. This breakthrough opens new opportunities for the application of high-performance engineering plastics in various industries, further advancing additive manufacturing capabilities.

“This success demonstrates Wisthink’s commitment to pushing the boundaries of 3D printing technology,” said a company spokesperson. “Our advanced high-temperature FDM 3D printer enables precise and reliable manufacturing with PEEK, expanding possibilities in industries that demand high-performance materials.”

With this innovation, Wisthink continues to drive progress in high-temperature 3D printing, paving the way for broader industrial adoption.

For more information, please contact:+44 07453951497